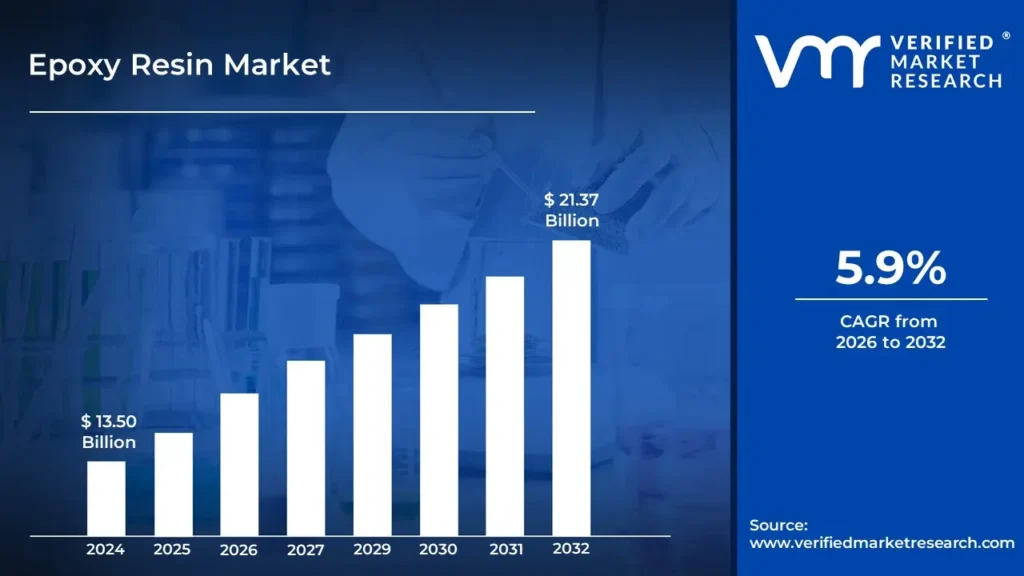

Epoxy Resin Market is expected to generate a revenue of USD 21.37 Billion by 2032, Globally, at 5.9% CAGR: Verified Market Research®

The epoxy resin market presents strong growth opportunities, especially in Asia-Pacific, where industrial expansion and infrastructure investments are driving demand. Market players should focus on high-growth sectors like automotive, electronics, and construction, where epoxy resins are critical. However, entry strategies must account for raw material price volatility and evolving environmental regulations. Investing in sustainable, low-VOC, or bio-based epoxy solutions can enhance compliance and competitiveness. Additionally, forming regional partnerships and optimizing local supply chains in APAC can mitigate cost pressures and regulatory risks, positioning companies for long-term success in this evolving market landscape.

Lewes, Delaware, July 07, 2025 (GLOBE NEWSWIRE) -- The Global Epoxy Resin Market Size is projected to grow at a CAGR of 5.9% from 2026 to 2032, according to a new report published by Verified Market Research®. The report reveals that the market was valued at USD 13.50 Billion in 2024 and is expected to reach USD 21.37 Billion by the end of the forecast period.

The epoxy resin market is witnessing substantial growth, supported by increasing usage in coatings, adhesives, and composites across multiple sectors. With superior mechanical strength and chemical resistance, epoxy resins are becoming integral to high-performance applications globally.

Key Highlights of the Report:

- Market Size & Forecast: In-depth analysis of current value and future projections

- Segment Analysis: Detailed study across Type, Application, and End User.

- Regional Insights: Comprehensive coverage of North America, Europe, Asia-Pacific, and more

- Competitive Landscape: Profiles of top players and their strategic initiatives

- Technology Breakdown: Focus on innovations in bio-based resins and low-VOC formulations.

- Challenges and Risk Assessment: Evaluates ethical debates, off-target effects, and regulatory complexities.

Why This Report Matters:

This report provides strategic insights to navigate the dynamic epoxy resin market, equipping stakeholders with actionable intelligence on pricing trends, innovation opportunities, supply chain risks, and competitor strategies—crucial for growth planning and investment decisions.

Who You Should Read This Report:

- Industrial Manufacturers & OEMs

- Chemical Industry Stakeholders

- Construction & Automotive Material Suppliers

- Investors & Equity Analysts

- Product Development Teams

- Sustainability and Regulatory Experts

For more information or to purchase the report, please contact us at: https://www.verifiedmarketresearch.com/download-sample/?rid=514908

For more information or to purchase the report, please contact us at: https://www.verifiedmarketresearch.com/download-sample/?rid=514908

Browse in-depth TOC on “Global Epoxy Resin Market Size”

202 - Pages

126 – Tables

37 – Figures

Report Scope

| REPORT ATTRIBUTES | DETAILS |

| STUDY PERIOD | 2021-2032 |

| GROWTH RATE | CAGR of ~5.9% from 2026 to 2032 |

| BASE YEAR FOR VALUATION | 2024 |

| HISTORICAL PERIOD | 2021-2023 |

| QUANTITATIVE UNITS | Value in USD Billion |

| FORECAST PERIOD | 2026-2032 |

| REPORT COVERAGE | Historical and Forecast Revenue Forecast, Historical and Forecast Volume, Growth Factors, Trends, Competitive Landscape, Key Players, Segmentation Analysis |

| SEGMENTS COVERED |

|

| REGIONS COVERED |

|

| KEY PLAYERS |

|

| CUSTOMIZATION | Report customization along with purchase available upon request |

Global Epoxy Resin Market Overview

Market Driver

Expanding Infrastructure and Construction Activities: The global construction sector is undergoing rapid transformation driven by increasing urbanization, population growth, and smart city initiatives, particularly in emerging economies like India, China, Brazil, and the UAE. Epoxy resins are extensively used in this sector due to their excellent mechanical strength, thermal stability, chemical resistance, and adhesion properties, making them ideal for industrial flooring, anti-corrosive coatings, grouts, sealants, and concrete repair systems. As governments implement large-scale infrastructure projects—including highways, metro systems, tunnels, commercial complexes, and renewable energy plants—the need for durable materials that ensure long service life and structural integrity is surging. Epoxy-based materials provide this durability, which makes them highly desirable in harsh environments. Additionally, the shift towards green buildings and low-maintenance construction materials is expected to further increase epoxy resin adoption.

Rising Adoption in Automotive and Aerospace Applications: The automotive and aerospace industries are significantly increasing their use of epoxy resins in response to evolving industry requirements such as fuel efficiency, lightweighting, and improved durability. Epoxy resins are used in manufacturing composite materials, adhesives, and protective coatings for automotive body panels, structural parts, battery systems, and interior components. Their low density and high mechanical performance align well with the growing trend of replacing metal parts with fiber-reinforced polymer composites to reduce overall vehicle weight. Similarly, in aerospace, epoxy resins are crucial for structural laminates, bonding agents, and as part of CFRP (carbon fiber reinforced plastic) composites that enhance aircraft performance and reduce fuel consumption. With increasing demand for electric vehicles (EVs), autonomous driving technology, and high-performance aircraft, epoxy resins are expected to witness sustained demand in these segments.

Growing Demand in Electrical and Electronics Industry: The global shift toward digitalization and automation is driving exponential growth in the electronics and electrical sector, directly impacting the demand for epoxy resins. These resins are vital in manufacturing printed circuit boards (PCBs), semiconductors, LED encapsulants, insulators, and electrical laminates due to their excellent dielectric properties, chemical inertness, flame resistance, and low shrinkage during curing. The proliferation of consumer electronics, 5G infrastructure, electric grids, smart homes, and industrial IoT devices has led to increased use of advanced epoxy formulations that offer higher thermal conductivity and miniaturization support. Moreover, as countries invest in renewable energy and electric mobility infrastructure, epoxy resins are being utilized in applications such as transformers, power generators, and electric motors. Their superior resistance to environmental stress and electrical interference makes them indispensable for long-term operational reliability in critical electronic applications.

To Purchase a Comprehensive Report Analysis: https://www.verifiedmarketresearch.com/select-licence/?rid=514908

To Purchase a Comprehensive Report Analysis: https://www.verifiedmarketresearch.com/select-licence/?rid=514908

Market Restraint

Volatility in Raw Material Prices: A major restraint impacting the epoxy resin market is the high dependency on petrochemical derivatives such as bisphenol-A (BPA) and epichlorohydrin (ECH) for production. These raw materials are vulnerable to crude oil price fluctuations, trade disruptions, and geopolitical instabilities. For instance, any disruption in the supply chain or geopolitical conflict in oil-producing nations can trigger sharp price hikes in feedstocks. This volatility hampers cost predictability and puts pressure on manufacturers’ profit margins, especially those with fixed-price contracts. Additionally, the growing global scrutiny on BPA due to its environmental and health risks adds another layer of uncertainty. These price dynamics challenge the financial planning and sustainability of small to mid-sized market players, often leading to reduced production efficiency, delayed deliveries, or loss of competitiveness in price-sensitive markets.

Environmental Regulations and Compliance Challenges: Environmental and regulatory restrictions are growing more stringent across global markets, particularly in regions like the European Union and North America. Regulations under frameworks such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the U.S. EPA limit the use of certain epoxy resin components due to concerns over toxicity, VOC emissions, and worker safety. Manufacturers are now compelled to invest heavily in R&D for low-VOC or bio-based alternatives, which increases production costs and lengthens time-to-market. Failure to comply with these standards may result in penalties, product recalls, or bans. Moreover, the growing emphasis on Environmental, Social, and Governance (ESG) standards from institutional investors is pushing manufacturers to adopt greener and circular approaches, which may require capital-intensive upgrades to production facilities, raw material sourcing, and end-of-life recycling strategies.

Challenges in Disposal and Recycling of Epoxy Composites: Epoxy resins, once cured, form thermoset polymers that are chemically cross-linked and cannot be remelted or reshaped. This characteristic, while beneficial for structural integrity, presents a major challenge in end-of-life disposal and recycling, particularly in industries like wind energy, aerospace, and automotive where epoxy-based composites are widely used. As global pressure for sustainable materials intensifies, companies are facing mounting criticism for the lack of recyclability of epoxy-based products. Current recycling technologies, such as pyrolysis or chemical recovery, are expensive, energy-intensive, and not yet scalable. Consequently, the accumulation of epoxy-based waste in landfills or incinerators raises environmental concerns and regulatory risks. The slow pace of innovation in recyclable epoxy formulations could hinder long-term market growth, especially in regions implementing strict circular economy policies.

Geographical Dominance: Asia-Pacific dominates the epoxy resin market, driven by rapid industrialization, urban infrastructure growth, and high-volume manufacturing in China, India, and Southeast Asia. The region’s expanding automotive, electronics, and construction sectors are major demand generators. Favorable government policies, low labor costs, and a robust supply chain ecosystem further strengthen its market position. Additionally, increasing foreign investments and rising exports from APAC continue to fuel regional expansion and innovation.

Key Players

The “Global Epoxy Resin Market” study report will provide a valuable insight with an emphasis on the global market. The major players in the market are Huntsman Corporation, Hexion Inc., Olin Corporation, Nan Ya Plastics Corporation, Kukdo Chemical Co., Ltd., Aditya Birla Chemicals, BASF SE, DuPont, 3M Company, Dow Chemical Company.

Epoxy Resin Market Segment Analysis

Based on the research, Verified Market Research has segmented the global market into Product Type, End User, Application, and Geography.

-

Epoxy Resin Market, by Product Type

- DGBEA

- DGBEF

- Novolac

- Aliphatic

- Glycidylamine

-

Epoxy Resin Market, by End-User

- Paints & Coatings

- Adhesives & Sealants

- Composites

- Electronic Encapsulation

- Construction

-

Epoxy Resin Market, by Application

- Construction

- Automotive

- Electronics

- Aerospace

- Marine

-

Epoxy Resin Market, by Geography

-

North America

- U.S

- Canada

- Mexico

-

Europe

- Germany

- France

- U.K

- Rest of Europe

-

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

-

ROW

- Middle East & Africa

- Latin America

-

North America

Browse Related Reports:

Global Industrial Grout Material Market Size By Type (Cementitious Grout, Epoxy Grout, Polyurethane Grout, Acrylic Grout), By Application (Mining, Oil & Gas, Power Generation, Water & Wastewater), By End-User (Residential, Commercial, Industrial, Infrastructure), By Geography, And Forecast

Global Resin Moulds Market Size By Type (Epoxy Resin Moulds, Polyurethane Resin Moulds, Silicone Resin Moulds, Polyester Resin Moulds), By Distribution Channel (Online Channels, Offline Channels), By Application (Automotive, Construction, Consumer Goods, Aerospace, Medical Devices), By End-User (Manufacturers, Design Studios, Educational and Research Institutions, Craftsmen & Artisans), By Geography, And Forecast

Global Carbon Fiber Prepreg Market Size By Fiber Type (Standard Modulus, Intermediate Modulus, High Modulus), By Resin System (Epoxy, BMI, Cyanate Ester), By End-User Industry (Aerospace, Automotive, Wind Energy), By Geography, And Forecast

Global High Temperature Composite Resin Market Size By Product (Phenolic, Epoxy), By Application (Aerospace And Defense, Transportation), By Geography, And Forecast

Top 7 Vinyl Ester Resin Manufacturers driving innovations in composite materials

Visualize Epoxy Resin Market using Verified Market Intelligence -:

Verified Market Intelligence is our BI Enabled Platform for narrative storytelling in this market. VMI offers in-depth forecasted trends and accurate Insights on over 20,000+ emerging & niche markets, helping you make critical revenue-impacting decisions for a brilliant future.

VMI provides a holistic overview and global competitive landscape with respect to Region, Country, Segment, and Key players of your market. Present your Market Report & findings with an inbuilt presentation feature saving over 70% of your time and resources for Investor, Sales & Marketing, R&D, and Product Development pitches. VMI enables data delivery In Excel and Interactive PDF formats with over 15+ Key Market Indicators for your market.

About Us

Verified Market Research® stands at the forefront as a global leader in Research and Consulting, offering unparalleled analytical research solutions that empower organizations with the insights needed for critical business decisions. Celebrating 10+ years of service, VMR has been instrumental in providing founders and companies with precise, up-to-date research data.

With a team of 500+ Analysts and subject matter experts, VMR leverages internationally recognized research methodologies for data collection and analyses, covering over 15,000 high impact and niche markets. This robust team ensures data integrity and offers insights that are both informative and actionable, tailored to the strategic needs of businesses across various industries.

VMR's domain expertise is recognized across 14 key industries, including Semiconductor & Electronics, Healthcare & Pharmaceuticals, Energy, Technology, Automobiles, Defense, Mining, Manufacturing, Retail, and Agriculture & Food. In-depth market analysis cover over 52 countries, with advanced data collection methods and sophisticated research techniques being utilized. This approach allows for actionable insights to be furnished by seasoned analysts, equipping clients with the essential knowledge necessary for critical revenue decisions across these varied and vital industries.

Verified Market Research® is also a member of ESOMAR, an organization renowned for setting the benchmark in ethical and professional standards in market research. This affiliation highlights VMR's dedication to conducting research with integrity and reliability, ensuring that the insights offered are not only valuable but also ethically sourced and respected worldwide.

Follow Us On: LinkedIn | Twitter | Threads | Instagram | Facebook

Attachment

Mr. Edwyne Fernandes Verified Market Research® US: +1 (650)-781-4080 US Toll Free: +1 (800)-782-1768 Email: sales@verifiedmarketresearch.com Web: https://www.verifiedmarketresearch.com/ SOURCE – Verified Market Research®

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.